Fuel Cell Hydrogen Pressurization Equipment: Powering the Future

2023-10-16

Introduction:

In the pursuit of cleaner and more sustainable energy sources, fuel cells have emerged as a promising technology. These devices convert the chemical energy of hydrogen fuel into electricity, producing only water vapor as a byproduct. However, to ensure optimal performance and efficiency, fuel cell systems require a reliable and efficient pressurization equipment. In this blog, we will delve into the world of fuel cell hydrogen pressurization equipment and explore its significance in advancing the future of clean energy.

The Role of Pressurization:

Pressurization plays a critical role in fuel cell systems. It is responsible for maintaining a steady supply of hydrogen gas at the desired pressure level to meet the fuel cell stack's requirements. Proper pressurization ensures efficient operation and enables the fuel cell system to deliver the power needed for various applications, including transportation, stationary power generation, and portable devices.

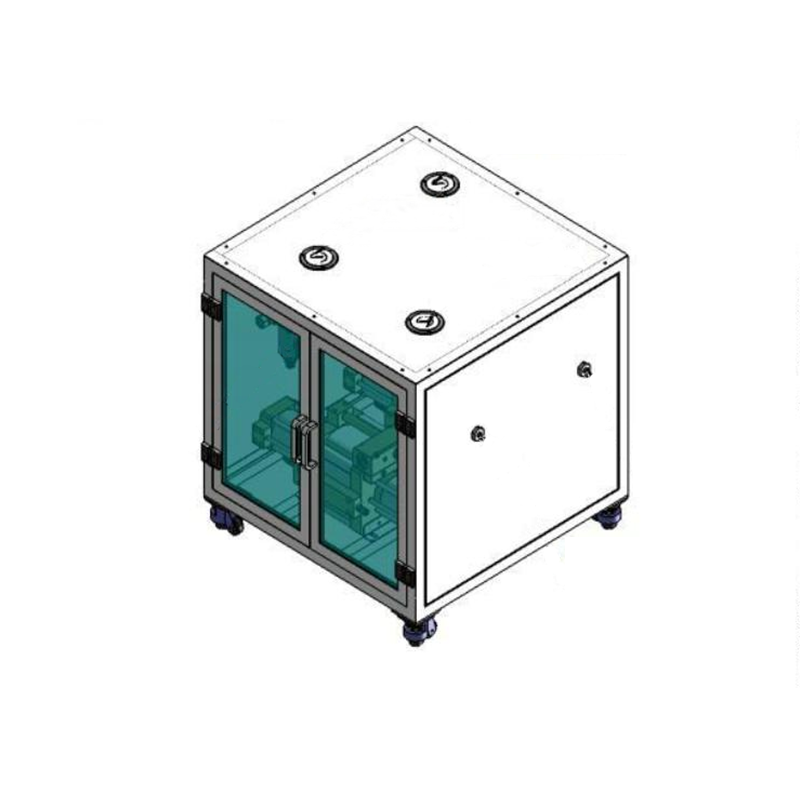

Components of Pressurization Equipment:

Fuel cell hydrogen pressurization equipment consists of several key components that work together to ensure the optimal performance of the system. Let's explore these components in detail:

1. Compressors:

Compressors are the heart of the pressurization system. They increase the pressure of the incoming hydrogen gas to the required level for the fuel cell stack. Various types of compressors, such as reciprocating, rotary screw, or centrifugal compressors, are employed based on factors like pressure levels, flow rates, and system design.

2. Pressure Regulators:

Pressure regulators play a crucial role in maintaining a constant and controlled pressure within the fuel cell system. They ensure that the hydrogen pressure delivered to the fuel cell stack remains within the specified range, optimizing performance and protecting the system from excessive pressure. Mechanical or electronic regulators are employed, or a combination of both, depending on the system requirements.

3. Accumulators:

To meet peak power demands or transient load conditions, accumulators or storage tanks store pressurized hydrogen gas. These tanks act as buffers, allowing for a steady supply of hydrogen gas at the desired pressure. They contribute to system stability and ensure a continuous and reliable fuel supply.

4. Safety Devices:

Given the importance of safety when dealing with hydrogen gas, pressurization systems incorporate various safety devices. Pressure relief valves, check valves, and rupture discs are employed to prevent overpressure situations and ensure safe operation of the system. These devices protect against the risk of hydrogen leaks or potential hazards caused by excessive pressure.

5. Piping and Fittings:

High-pressure piping and fittings are used to transport hydrogen gas between different components of the pressurization system. These components are designed to withstand the specific pressure and temperature requirements of hydrogen gas. Careful selection and installation of appropriate materials and fittings are crucial to ensure system integrity and prevent leaks.

6. Sensors and Controls:

Fuel cell pressurization systems utilize sensors, such as pressure sensors, flow meters, and temperature sensors, to monitor key parameters within the system. Control systems use this data to regulate the operation of compressors, pressure regulators, and other components. These sensors and controls help maintain optimal performance, efficiency, and safety of the pressurization equipment.

Advancing Clean Energy:

Fuel cell hydrogen pressurization equipment plays a vital role in advancing the adoption of clean energy solutions. By enabling the efficient and reliable operation of fuel cell systems, it contributes to reducing greenhouse gas emissions and dependence on fossil fuels. Fuel cells are being increasingly employed in various sectors, including transportation, residential and commercial power generation, and portable devices, driving the transition to a cleaner and more sustainable future.

Conclusion:

Fuel cell hydrogen pressurization equipment forms a critical part of fuel cell systems, ensuring the efficient delivery of power for a wide range of applications. The combination of compressors, pressure regulators, accumulators,safety devices, piping, and sensors work in harmony to maintain optimal pressure levels, reliability, and safety. As the world continues to embrace cleaner energy sources, fuel cell technology, supported by robust pressurization equipment, holds great promise in reshaping our energy landscape and driving us towards a greener and more sustainable future.