MLCC Machine Market Trends: Driving the Capacitor Industry Forward

2025-04-18

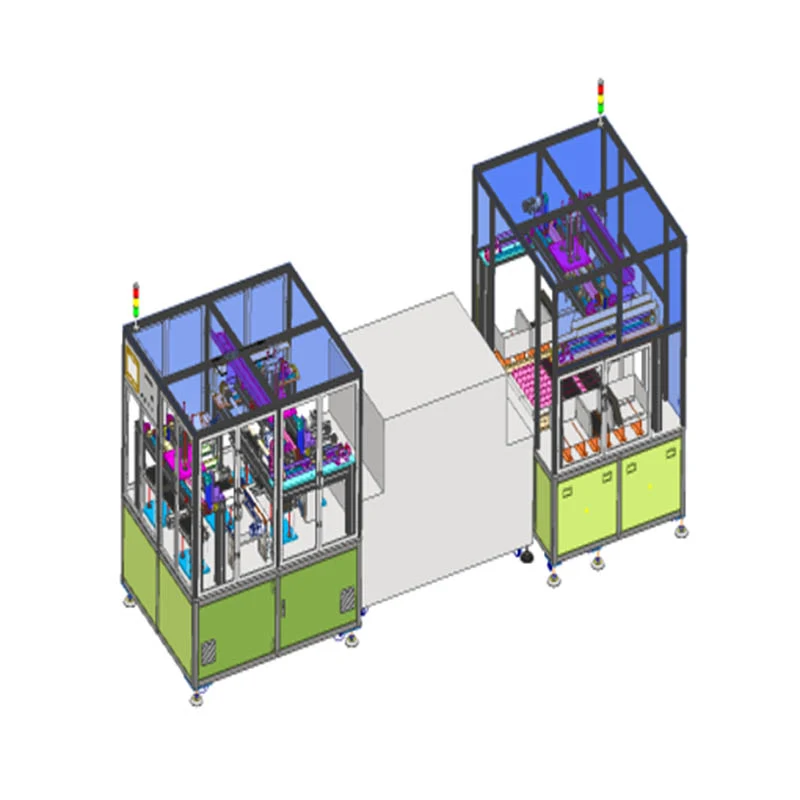

The global demand for Multilayer Ceramic Capacitors (MLCCs) has exploded in recent years, and at the heart of this growth is the MLCC machine. These highly automated production systems are not just factory tools — they are strategic assets for electronics manufacturers worldwide.

What’s Fueling the MLCC Boom?

1. 5G and IoT Expansion

New-age devices require more MLCCs for data transmission, energy efficiency, and miniaturization.

2. Electric Vehicles (EVs)

EVs need thousands of MLCCs per vehicle for everything from power control to infotainment systems.

3. Consumer Electronics Growth

With smart wearables and portable gadgets becoming mainstream, the need for smaller, more efficient capacitors has grown exponentially.

MLCC Machines: A Hot Investment Sector

Manufacturers across Asia — especially in South Korea, Japan, China, and Taiwan — are ramping up investments in MLCC machine technology. Key players in machine manufacturing are:

- TOKYO KEIKI

- Murata Machinery

- TAIYO YUDEN equipment division

- Custom machine builders in China and South Korea

These companies are constantly improving the speed, automation level, and AI integration of their machines.

Trends in MLCC Machine Technology

1. AI-Powered Inspection

Modern MLCC machines now use AI-based visual inspection systems to detect micro-defects instantly.

2. Miniaturization Compatibility

Machines are now capable of producing ultra-small MLCCs (as small as 008004 inch) with tighter tolerances.

3. Sustainable Manufacturing

Energy-efficient furnaces and eco-friendly material handling are becoming standard in high-end machines.

4. Modular Design

To meet demand fluctuations, modular machines allow rapid scale-up or product line changes.

Challenges Ahead

- High Initial Cost

Advanced MLCC machines require significant capital investment.

- Skilled Labor Shortage

Operating and maintaining such complex systems requires specialized talent.

- Supply Chain Bottlenecks

The rare materials needed for MLCCs and their machines can be subject to global trade fluctuations.

Looking Forward

As we step into an era dominated by AI, EVs, and hyper-connected smart devices, the importance of MLCCs — and the machines that make them — will only grow. Companies that invest early in next-gen MLCC machines will be better positioned to lead the electronic components race.