What Is Polyacrylamide Used For?

2025-09-01

Polyacrylamide (PAM) is a versatile water-soluble polymer with a wide range of applications across numerous industries. Its unique properties, such as flocculation, thickening, and friction reduction, make it an indispensable chemical. This article will explore the primary uses of polyacrylamide and detail the product parameters that define its effectiveness.

Key Applications of Polyacrylamide

One of the most significant uses of polyacrylamide is in water treatment plants. It acts as a flocculant, binding fine particles together into larger clumps, making them easier to remove from water. This process is crucial for producing clean drinking water and treating industrial wastewater. The oil and gas industry also relies heavily on it for drilling fluid viscosity and as a friction reducer. Furthermore, in the agricultural sector, polyacrylamide is used to prevent soil erosion and improve water retention.

Understanding Our Product Parameters

Our polyacrylamide is engineered to meet specific industrial demands. The product comes in various forms and ionic types, each tailored for different applications. Key parameters include ionic degree, molecular weight, and solubility. These factors directly influence the polymer's performance in flocculation, sedimentation, and clarification processes.

We produce several types of polyacrylamide to suit diverse needs:

1. Anionic Polyacrylamide: Best for wastewater treatment and mineral processing.

2. Cationic Polyacrylamide: Ideal for sludge dewatering and paper manufacturing.

3. Nonionic Polyacrylamide: Used in soil conditioning and textiles.

For a precise overview, here is a table of our standard product specifications:

| Parameter | Specification |

| Ionic Type | Anionic, Cationic, Nonionic |

| Molecular Weight | 5 - 25 million |

| Solid Content | ≥ 90% |

| Dissolution Time | ≤ 60 minutes |

| Residual Monomer | ≤ 0.05% |

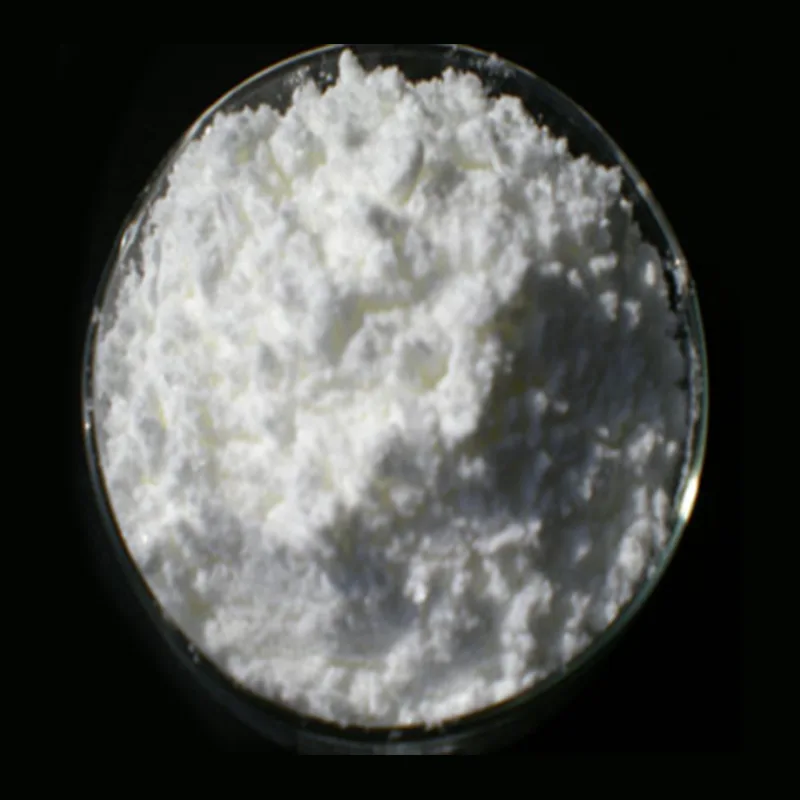

| Appearance | White granular powder or crystals |

Our factory utilizes advanced technology to ensure every batch of polyacrylamide meets these stringent parameters, guaranteeing consistent and reliable performance for our clients.

Frequently Asked Questions

Q1: What is the difference between anionic and cationic polyacrylamide?

The key difference lies in their ionic charge and subsequent applications. Anionic polyacrylamide carries a negative charge and is primarily used for mineral processing and clarifying inorganic sludges. Cationic polyacrylamide carries a positive charge, making it highly effective for organic sludge dewatering in municipal wastewater treatment and the paper industry, as it binds negatively charged particles.

Q2: Is polyacrylamide safe for use in drinking water treatment?

Yes, when used in accordance with strict guidelines. Polyacrylamide itself is non-toxic. The safety concern revolves around the trace amounts of acrylamide monomer. However, our production process at Nuoer is rigorously controlled to ensure ultra-low residual monomer content, well below the limits set by international health and safety standards, making it safe for potable water treatment.

Why Choose Nuoer for Your Polyacrylamide Needs

Selecting Nuoer as your supplier means investing in quality and expertise. Our commitment to research and development allows us to offer high-performance products tailored to complex industrial challenges. Our factory is equipped with state-of-the-art manufacturing and quality control systems, ensuring that every shipment meets our high standards for purity and effectiveness. Contact Nuoer Energy today to discuss your specific requirements and how our polyacrylamide products can benefit your operations.